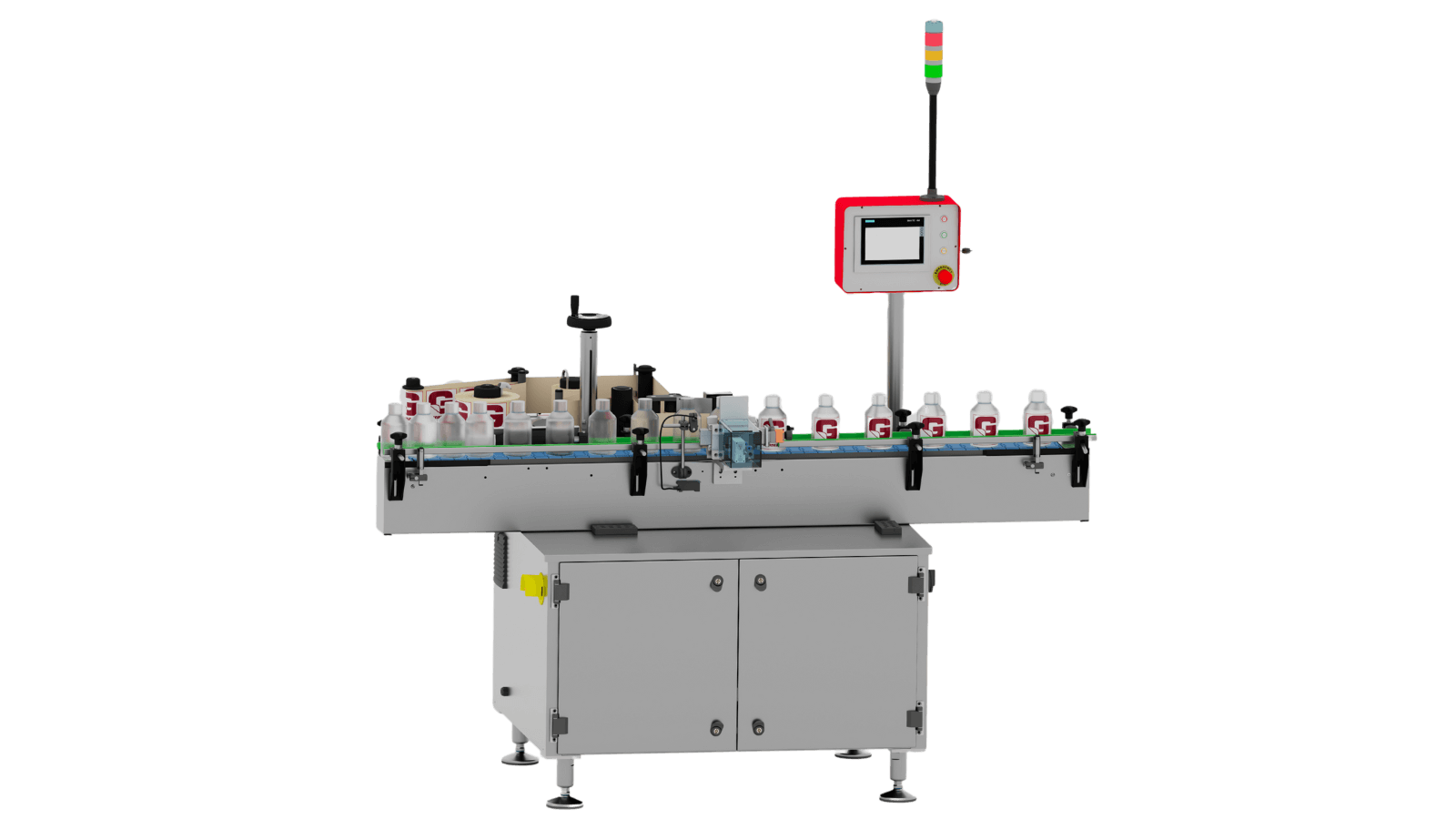

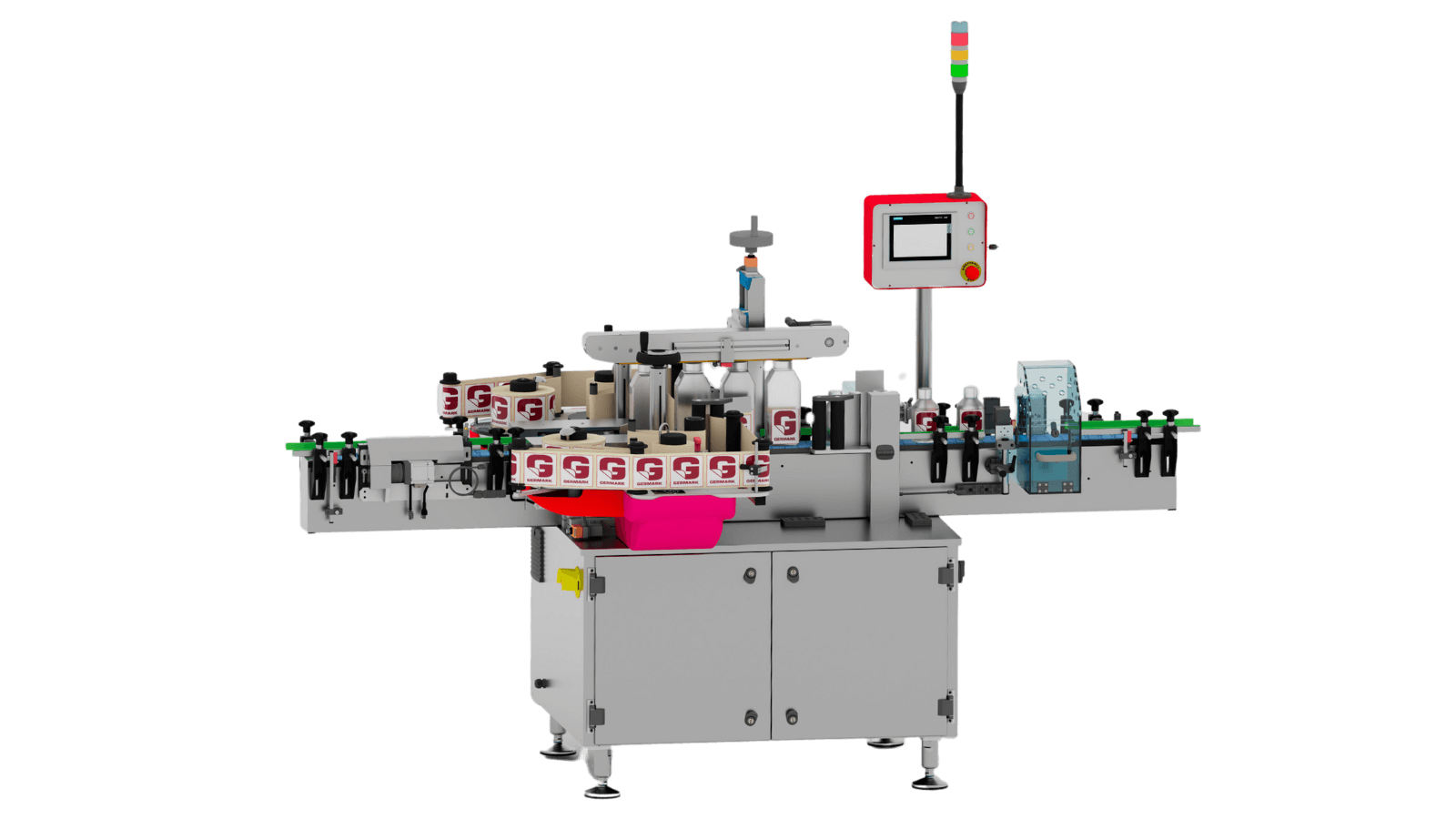

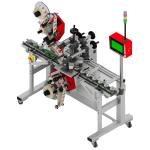

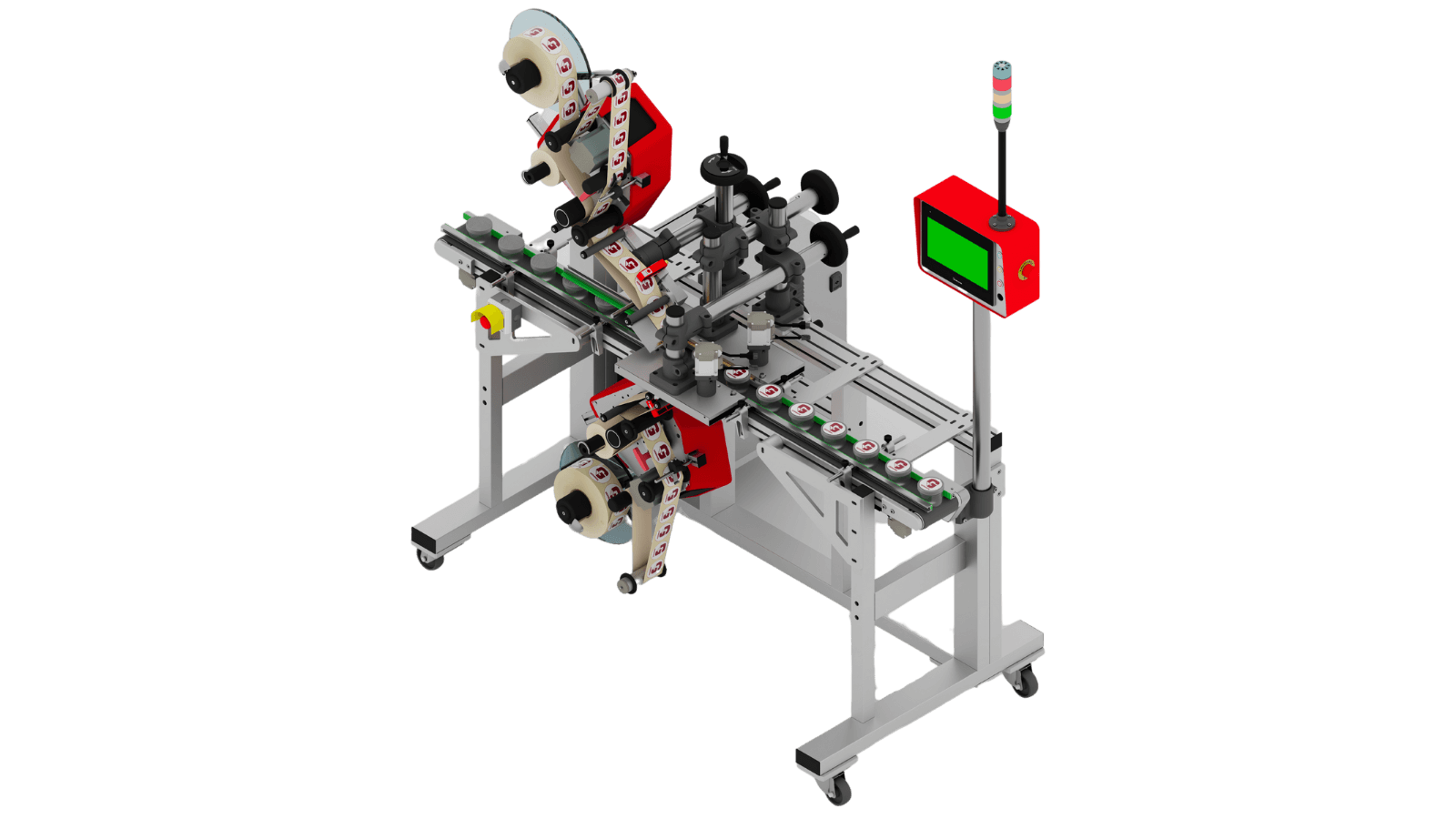

Linear labeling machines

Linear labeling machines are designed to apply labels accurately and efficiently to products moving along a production line. They are ideal for industries requiring fast and continuous labeling.

At Germark, our linear labeling machines can be directly integrated into a production line or operate independently with the addition of rotary tables at the beginning and end of the machine. These tables stack the products at the start and collect or accumulate them at the end, optimizing workflow.

Additionally, we offer automatic and semi-automatic models, allowing us to adapt to each customer’s specific needs while ensuring flexibility and efficiency in labeling.

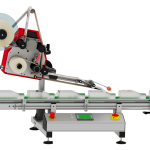

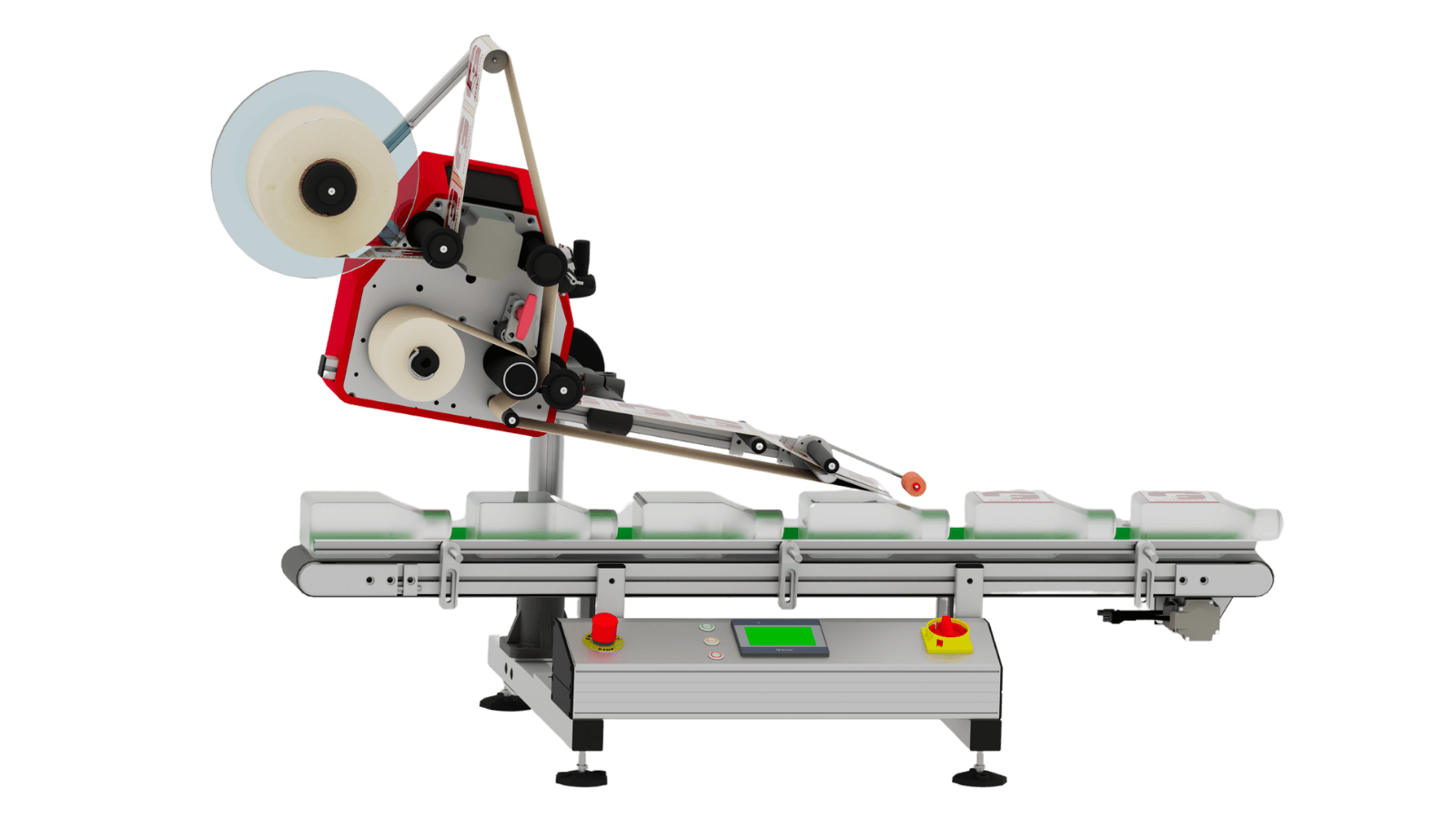

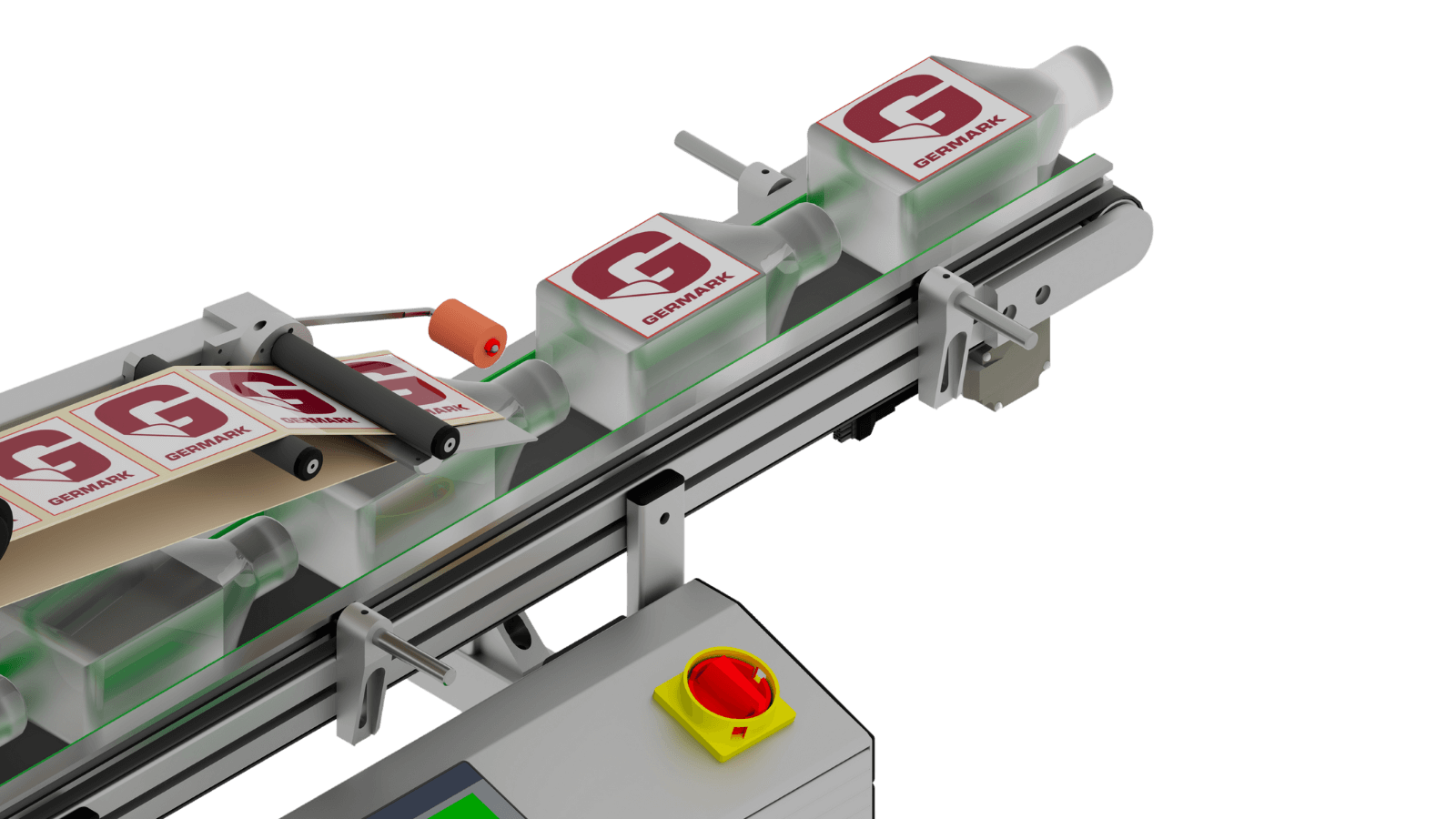

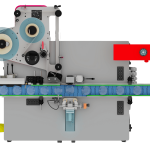

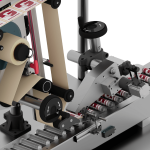

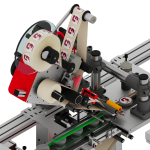

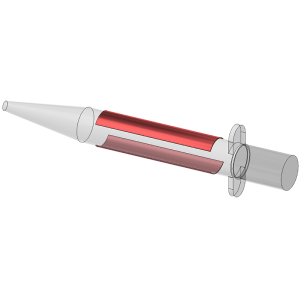

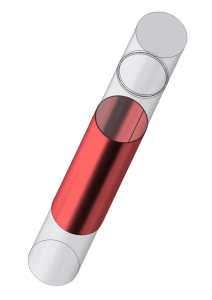

Minilabeler

Linear labeling machines

- Multilingual OLED display

- Adjustable speed up to 20 meters/minute

- Label counter

- Multi-label function

- High-brightness, large-size display

- End-of-roll control system

- Storage system for different formats

- Printer

- Product collection tray

- Cylindrical

- Rectangular

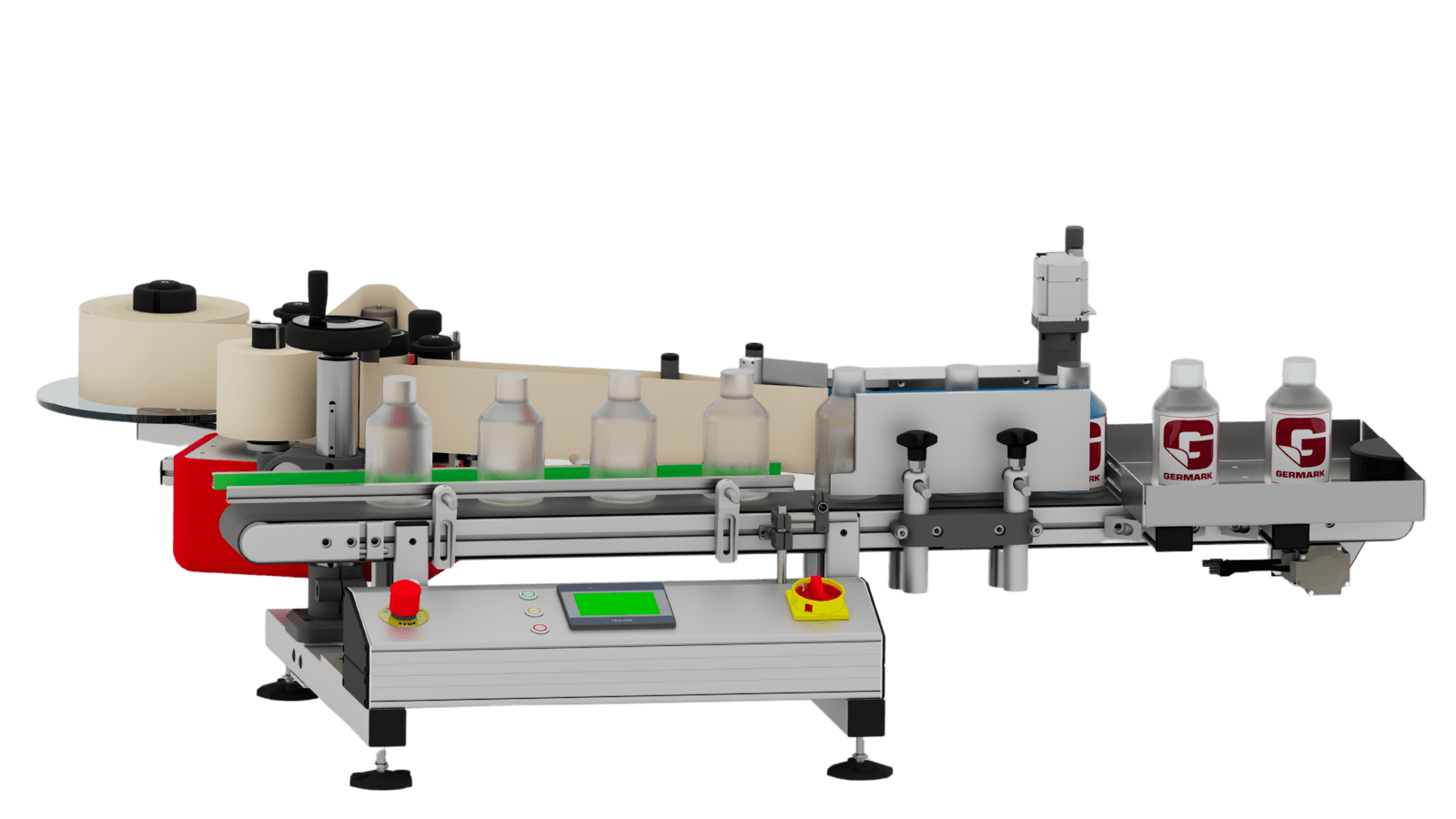

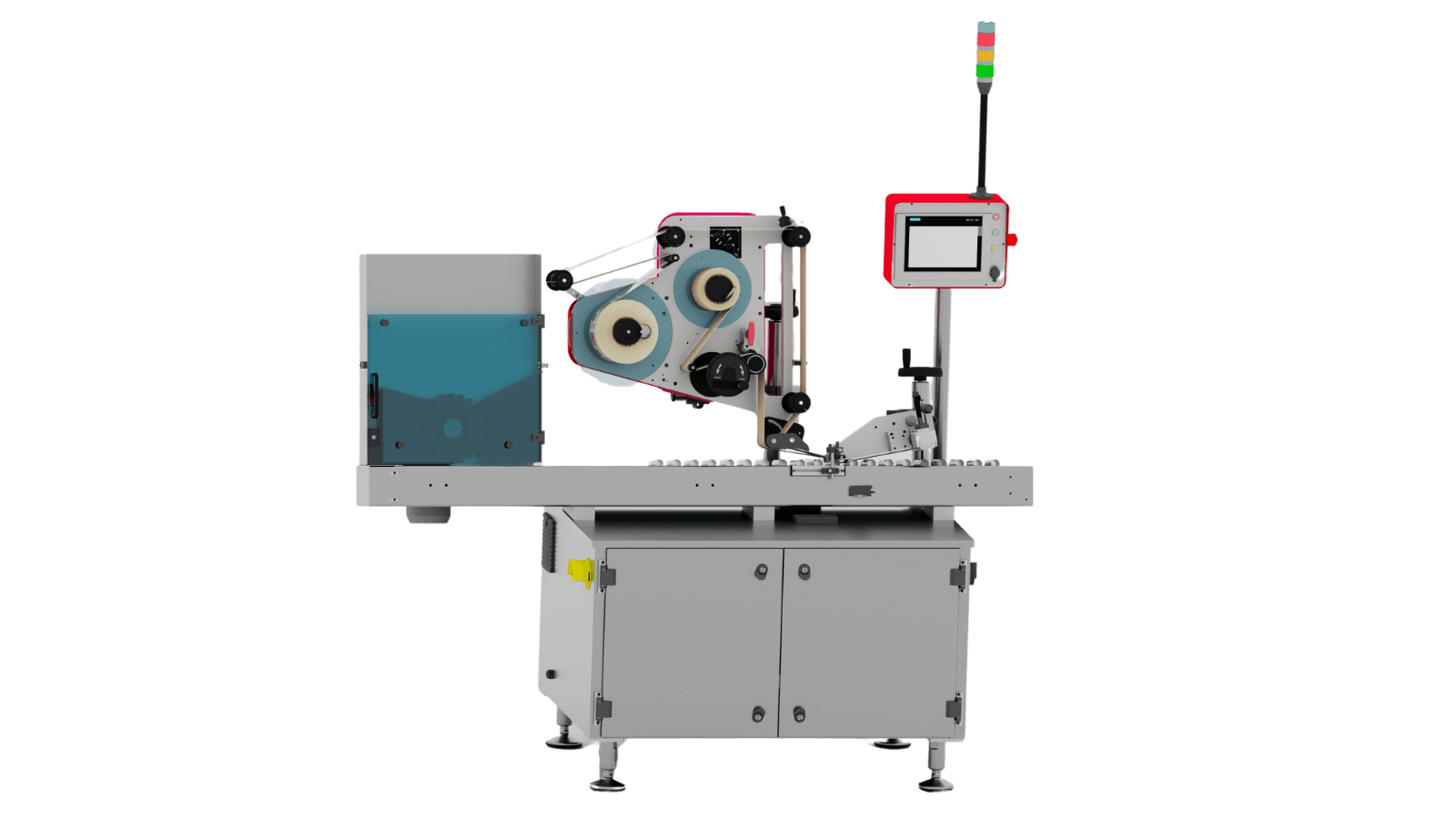

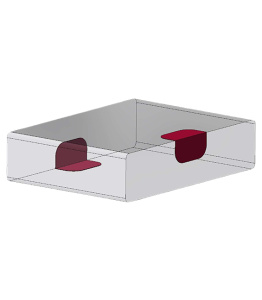

Basic

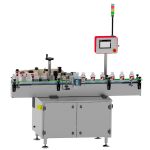

Linear labeling machines

- Compact design with low energy consumption and high precision

- Integrated control panel (touchscreen or membrane)

- High-brightness, large-size display

- Synchronized speeds

- Missing label detection

- Label counter

- Cadence up to 115 ppm

- Printer

- Positioned labeling

- Product distancer

- End of reel control

- Paper break control

- Entry/exit product accumulation control

- Storage system for different formats

- Variable data detection camera (OCR)

- Label/product detection camera

- Non-conforming product rejection

- Beacon

- Basic 50: Top labeling on one side

- Basic Total 100: Side labeling on one side

- Basic Total 200: Side labeling on 1 or 2 sides, positioned

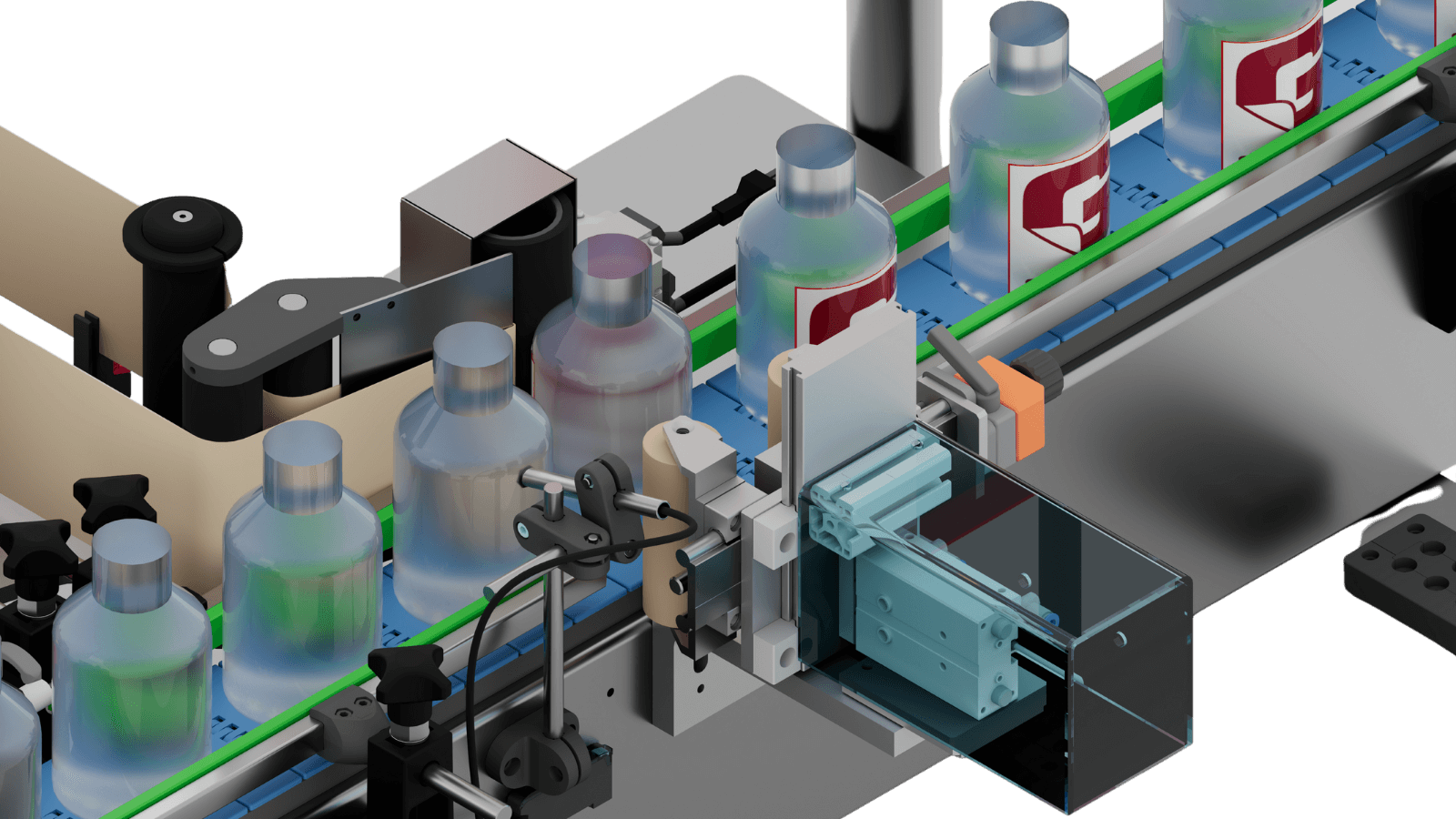

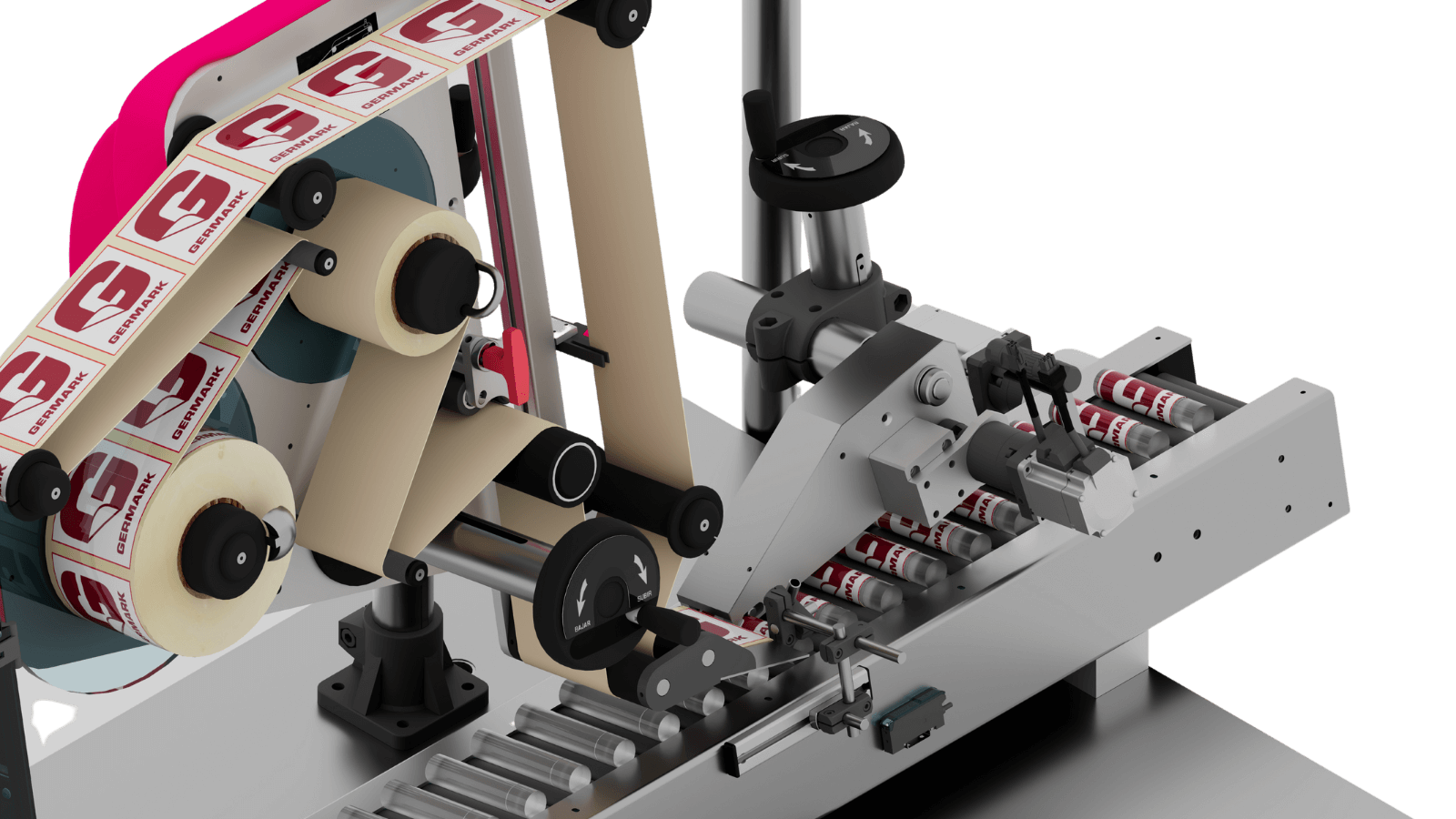

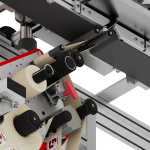

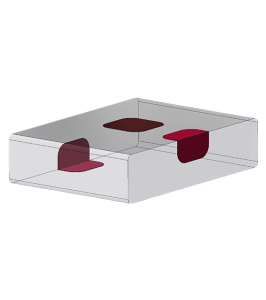

Cadence

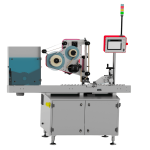

Linear labeling machines

- High-performance with low energy consumption

- Synchronized speeds

- Integrated control panel

- Fast format change

- Labeling unit control

- High-brightness control panel

- Adjustable label pre-positioning and positioning in mm

- Adjustable labeling speed in m/min

- Cadence up to 200 ppm

- Printer

- End of reel control

- Paper break control

- Storage system for different formats

- Variable data detection camera (OCR)

- Label/product detection camera

- Non-conforming product rejection

- Beacon

- Automatic feeder

- CFR21 compliance

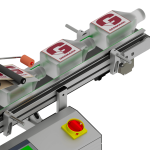

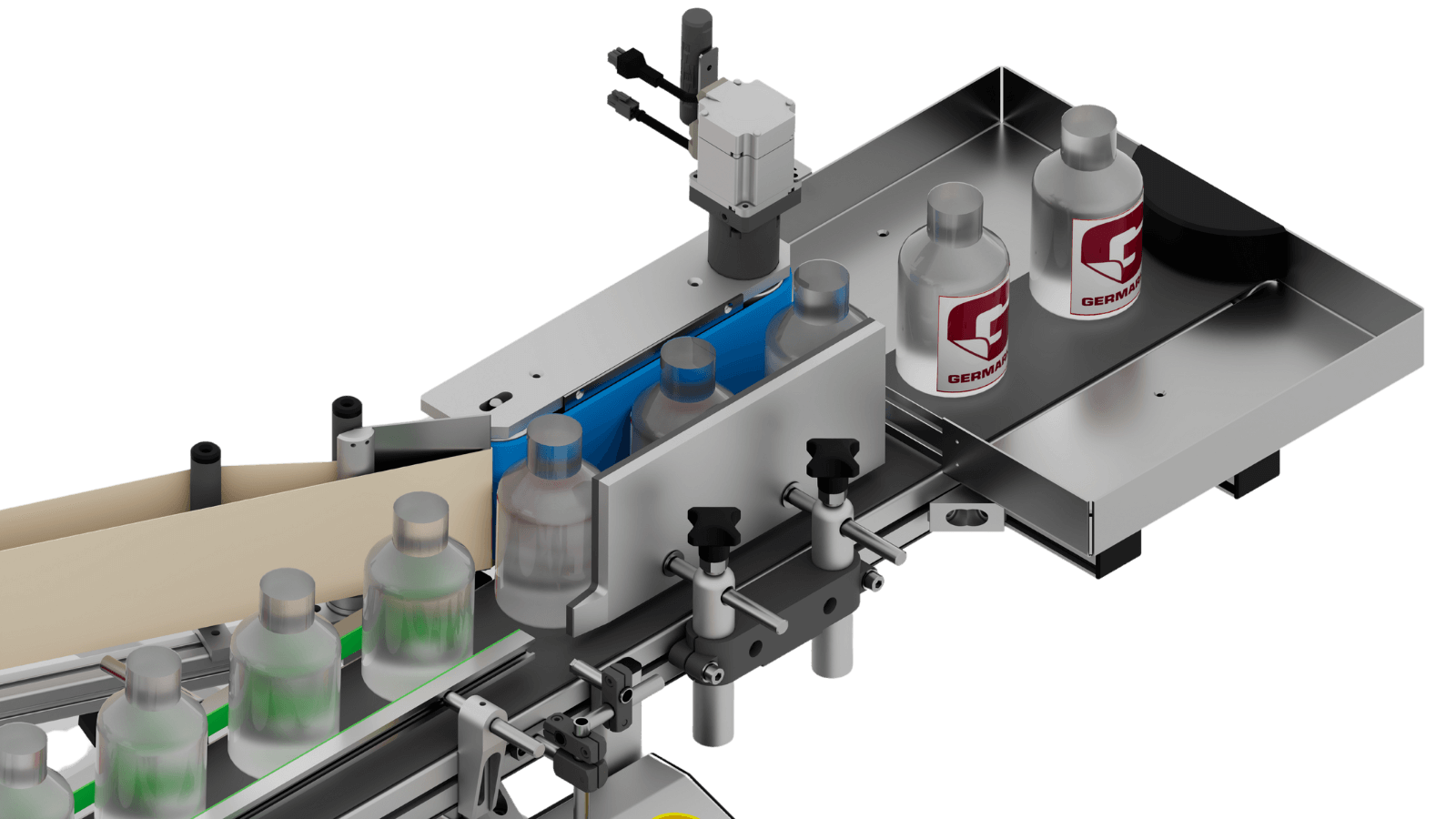

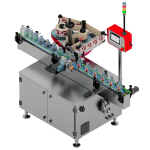

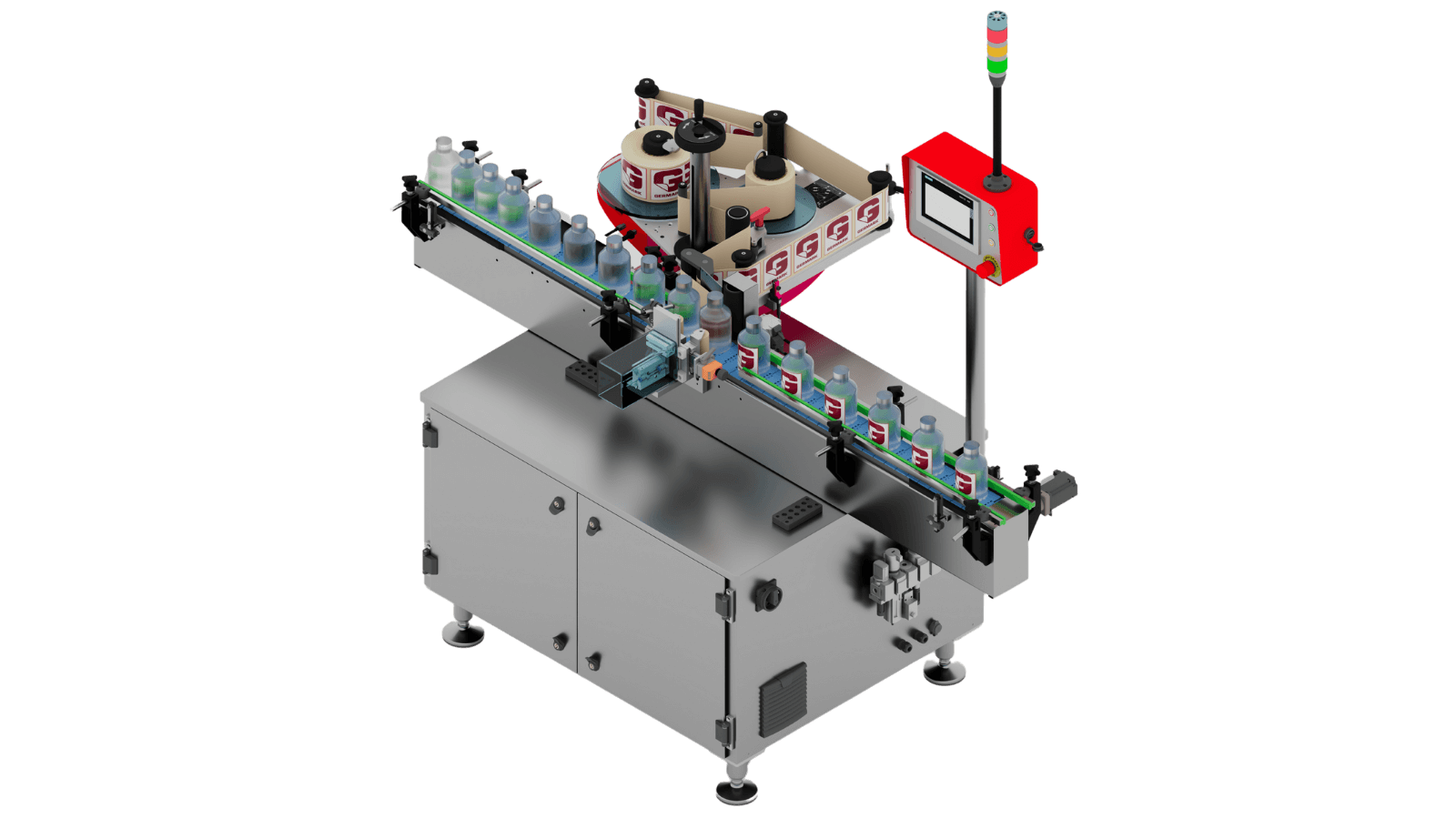

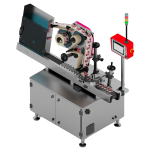

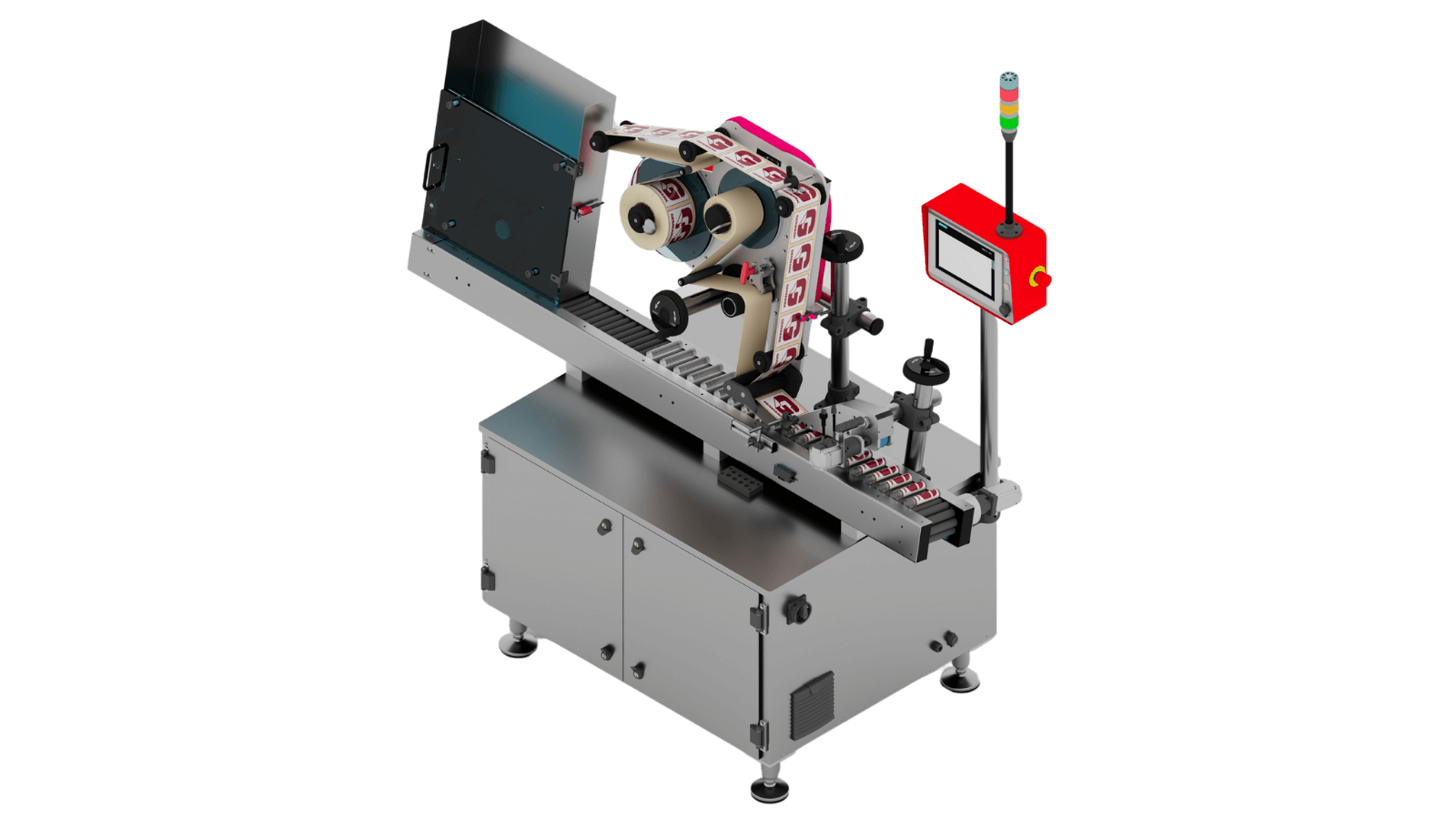

Sequence

Linear labeling machines

- Compact design with low energy consumption and high precision

- Synchronized speeds

- Integrated control panel (touchscreen or membrane)

- End-of-roll control

- Throughput of up to 200 ppm

- Printer

- Positioned labeling

- Product spacer

- End-of-roll control

- Paper break control

- Storage system for different formats

- Entry/exit product accumulation control

- Variable data detection camera (OCR)

- Label/product detection camera

- Non-conforming product ejection

- Beacon

- CFR21

- Sequence 200 / 3

- Sequence 200 / 4

- Sequence 300 / 3

- Sequence 300 / 4

- Sequence 400 / 3

- Sequence 400 / 4

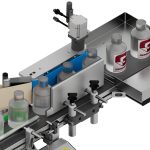

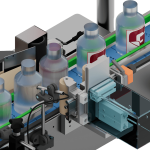

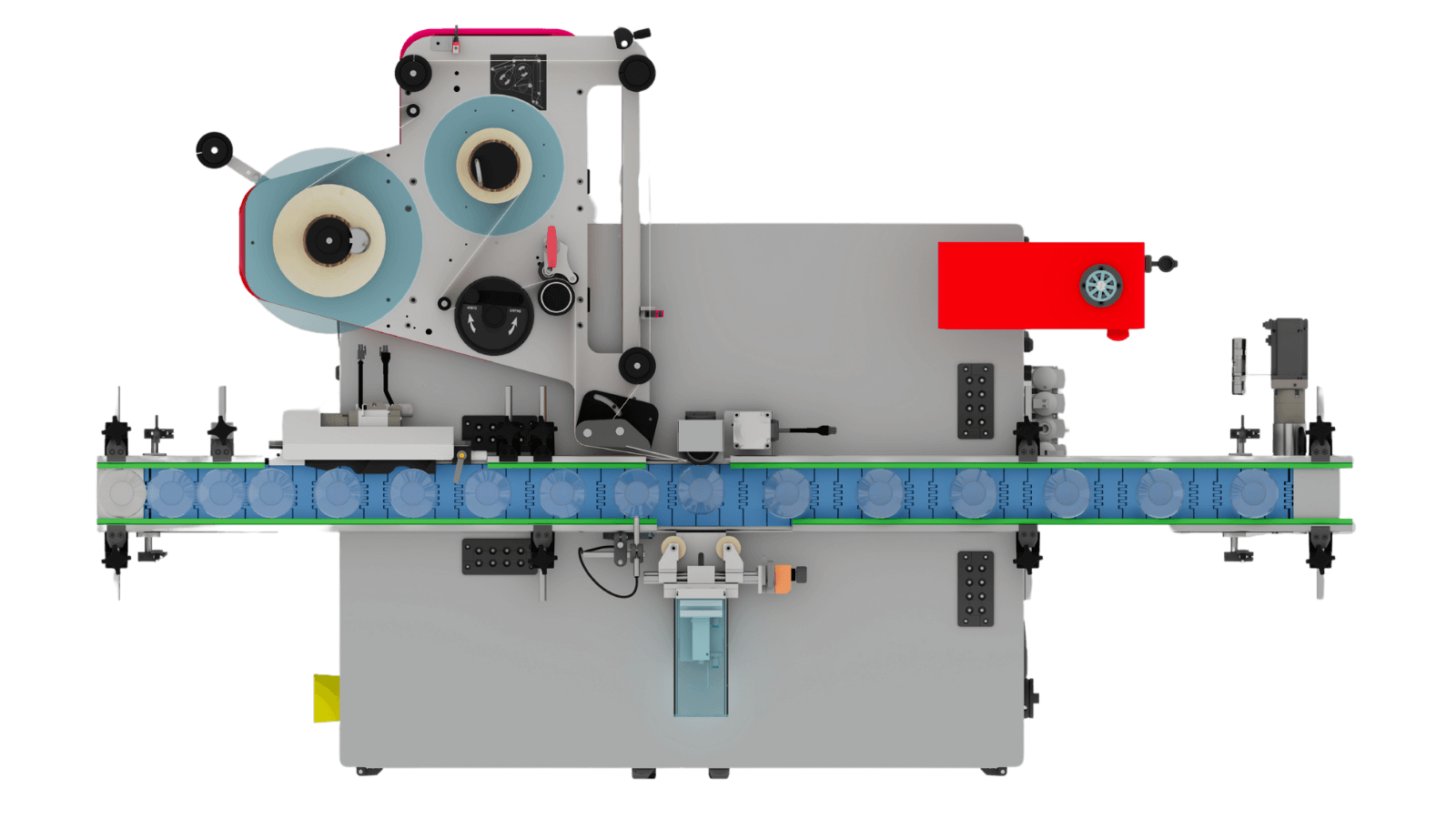

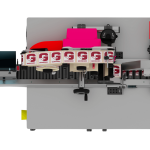

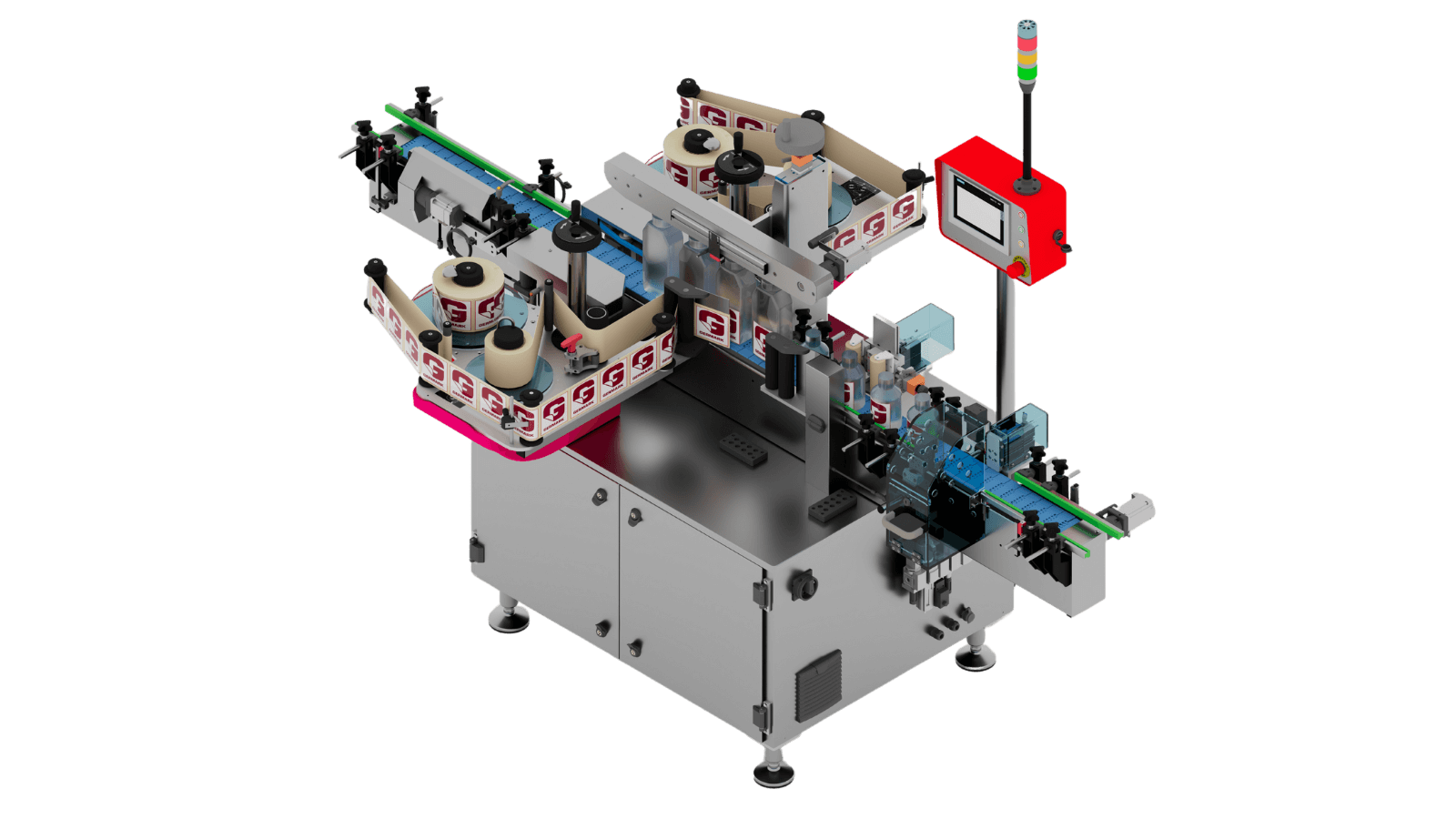

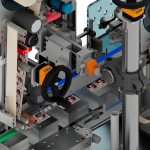

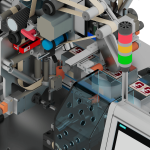

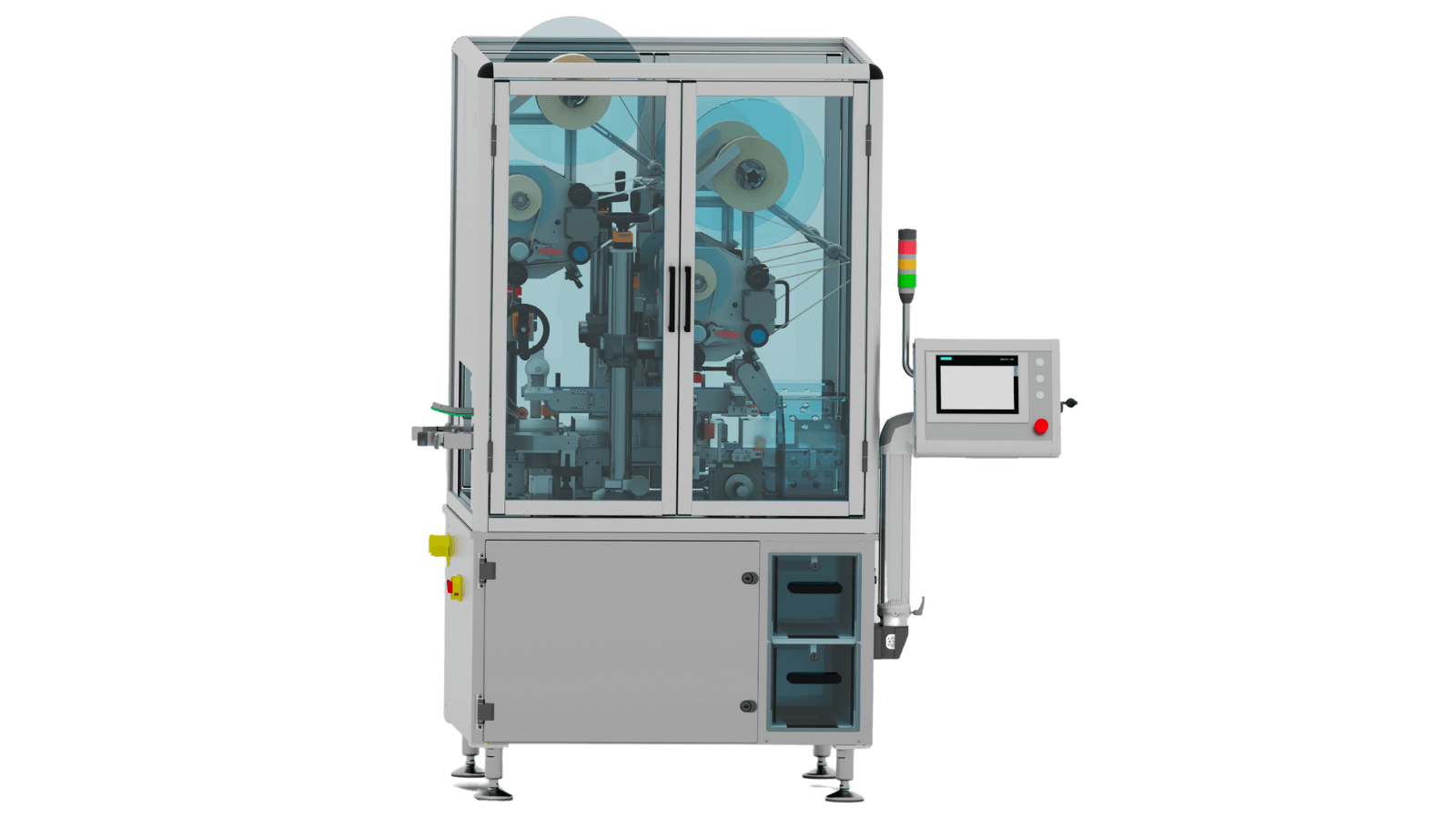

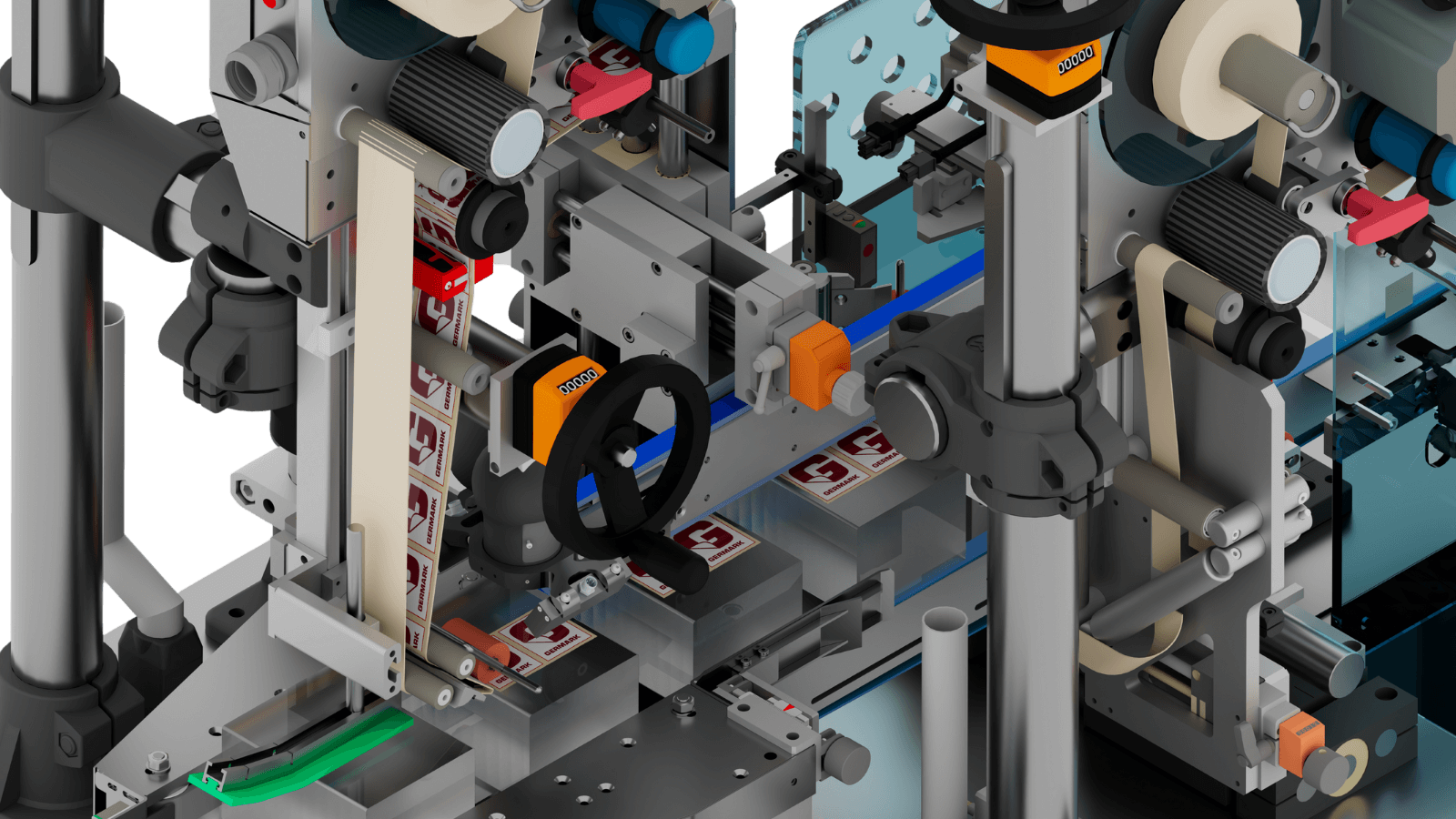

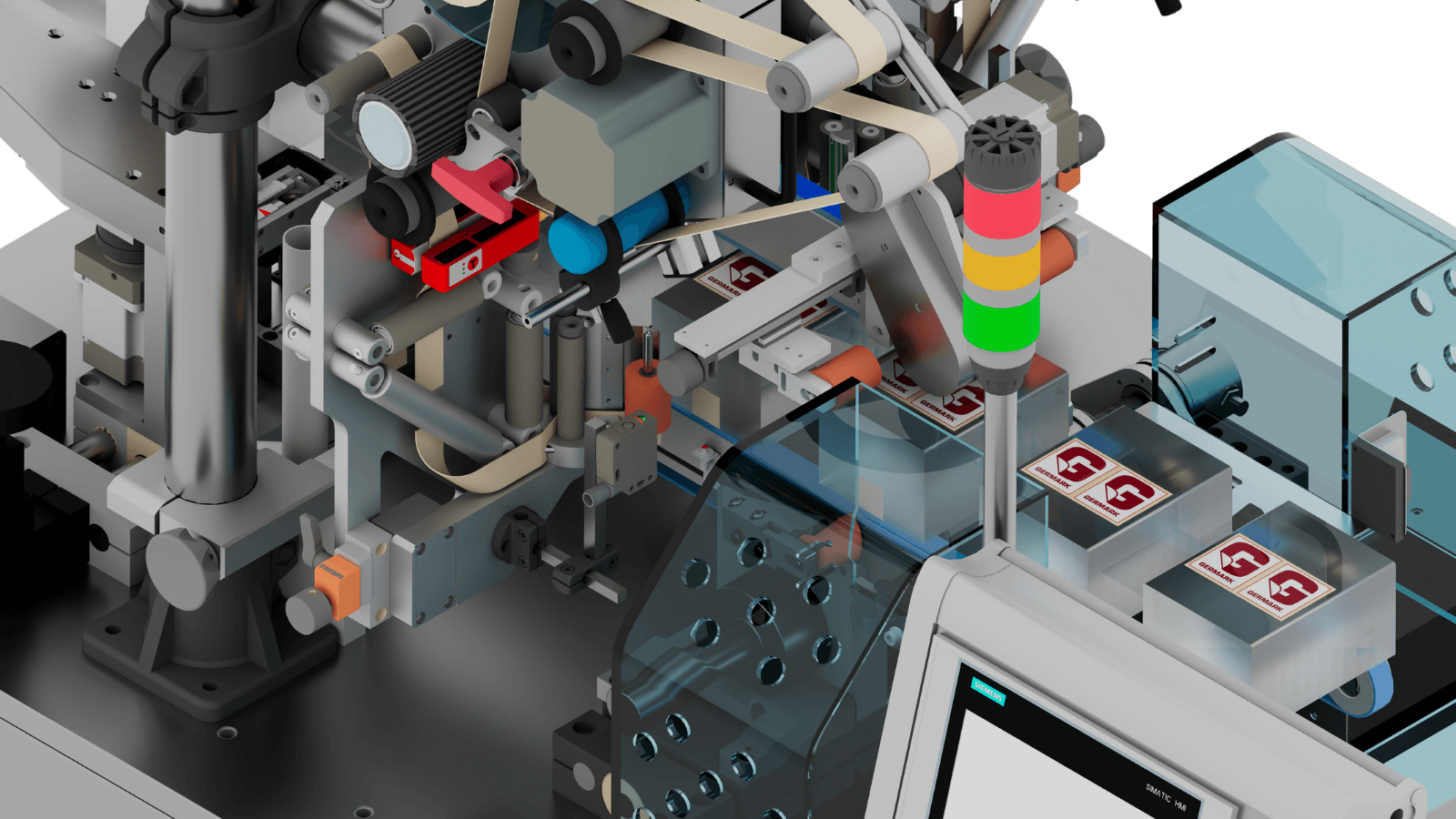

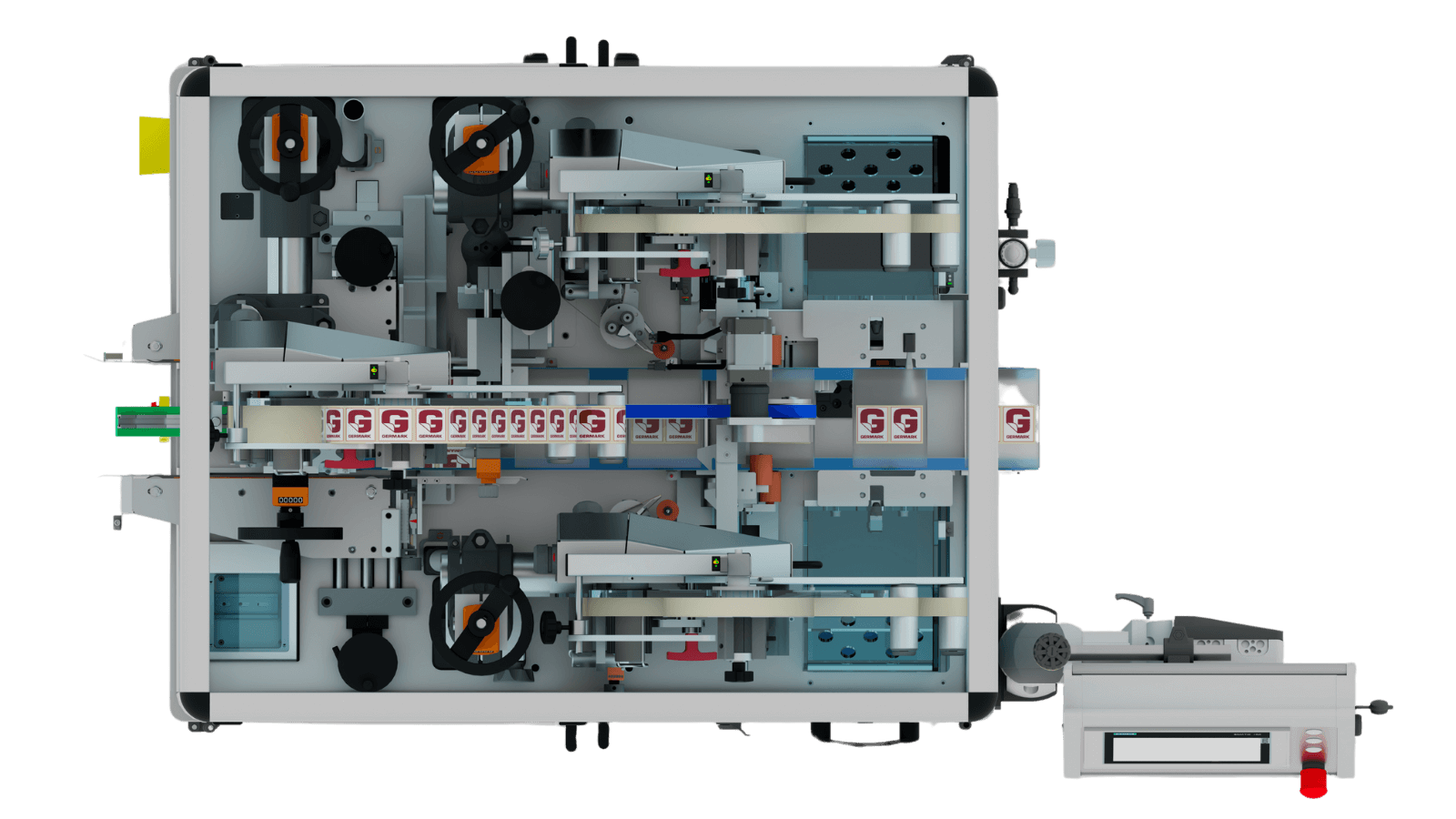

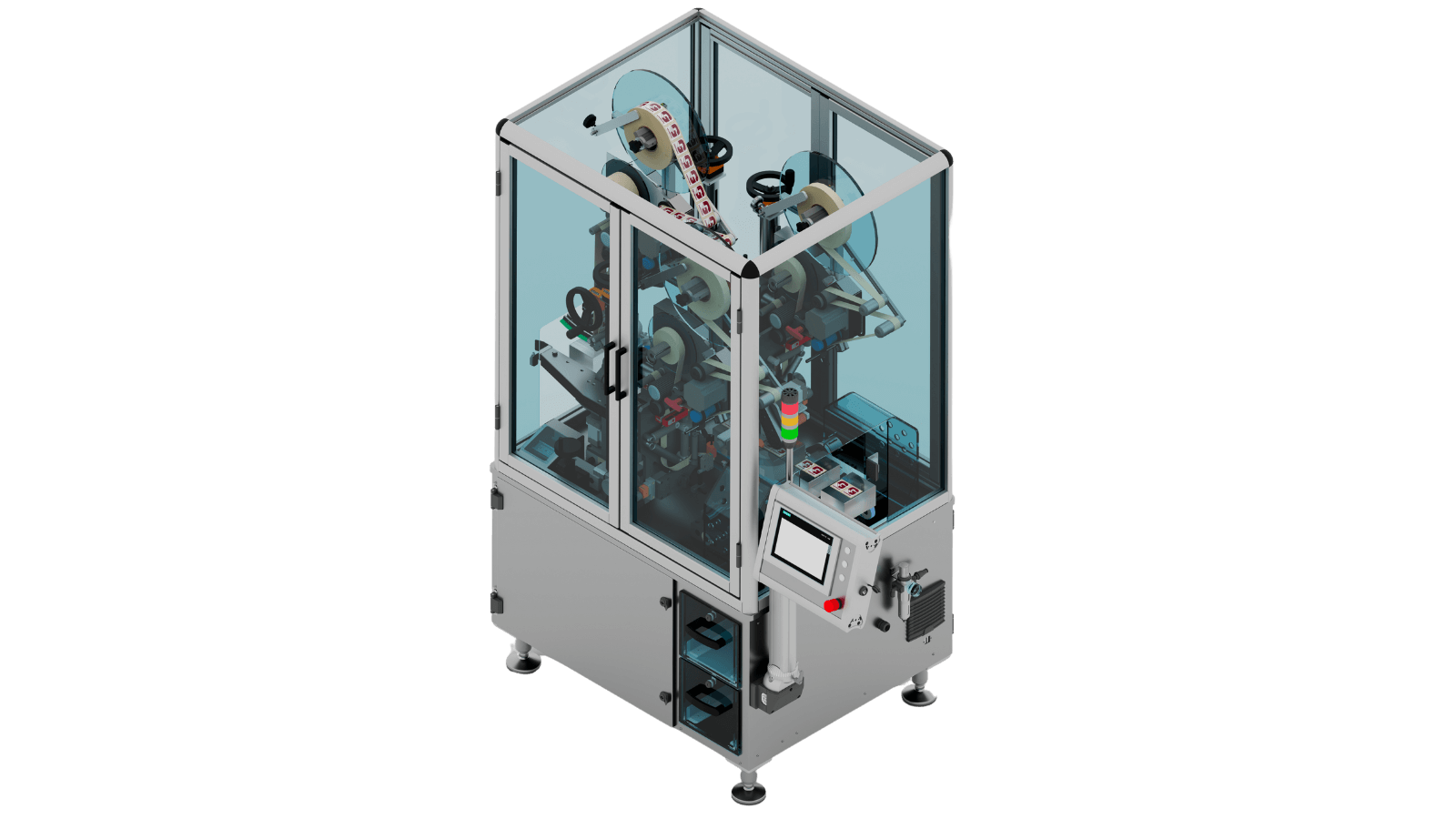

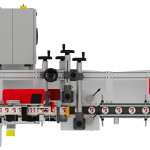

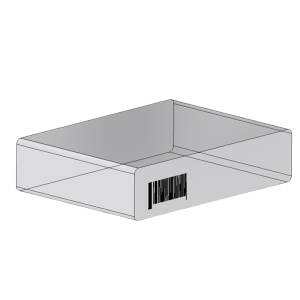

Multibox

Linear labeling machines

- Cadence up to 350 ppm

- End of reel control

- Paper break control

- Storage system for different formats

- Non-conforming product rejection

- Beacon

- Upper and lower belts controlled by servo motors

- No tools required for format change

- Product distancer

- Printer

- Variable data detection camera (OCR)

- Label/product detection camera (sensor)

- Easy integration with serialization systems

- CFR21

- S: Serialization

- TE: Tamper Evident

- STE: Serialization + Tamper Evident

- SVTE: Serialization + Vignette + Tamper Evident

- STE-CW: Serialization + Tamper Evident + Check Weight

- SVTE-CW: Serialization + Vignette + Tamper Evident + Check Weight

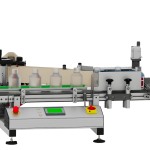

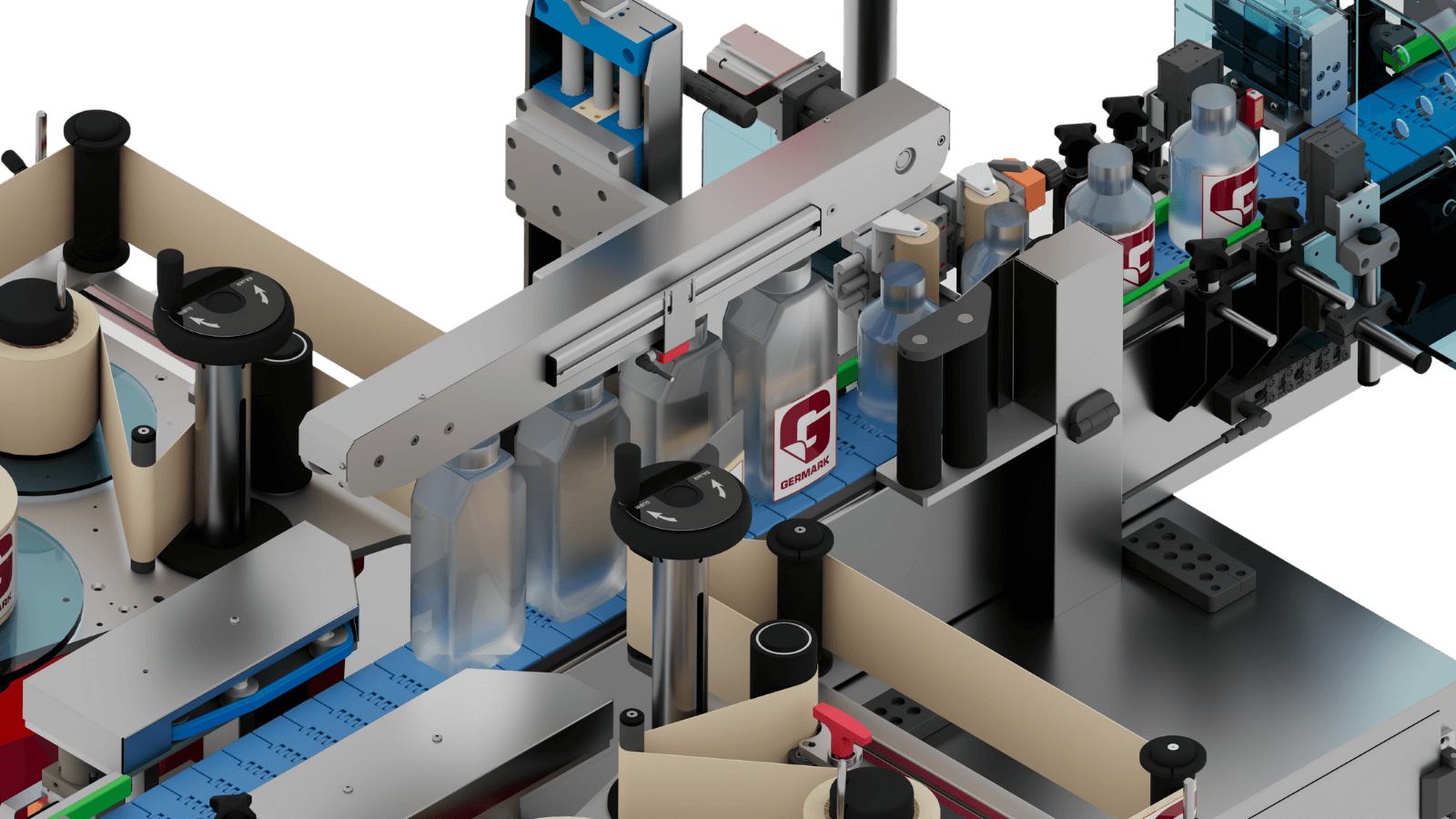

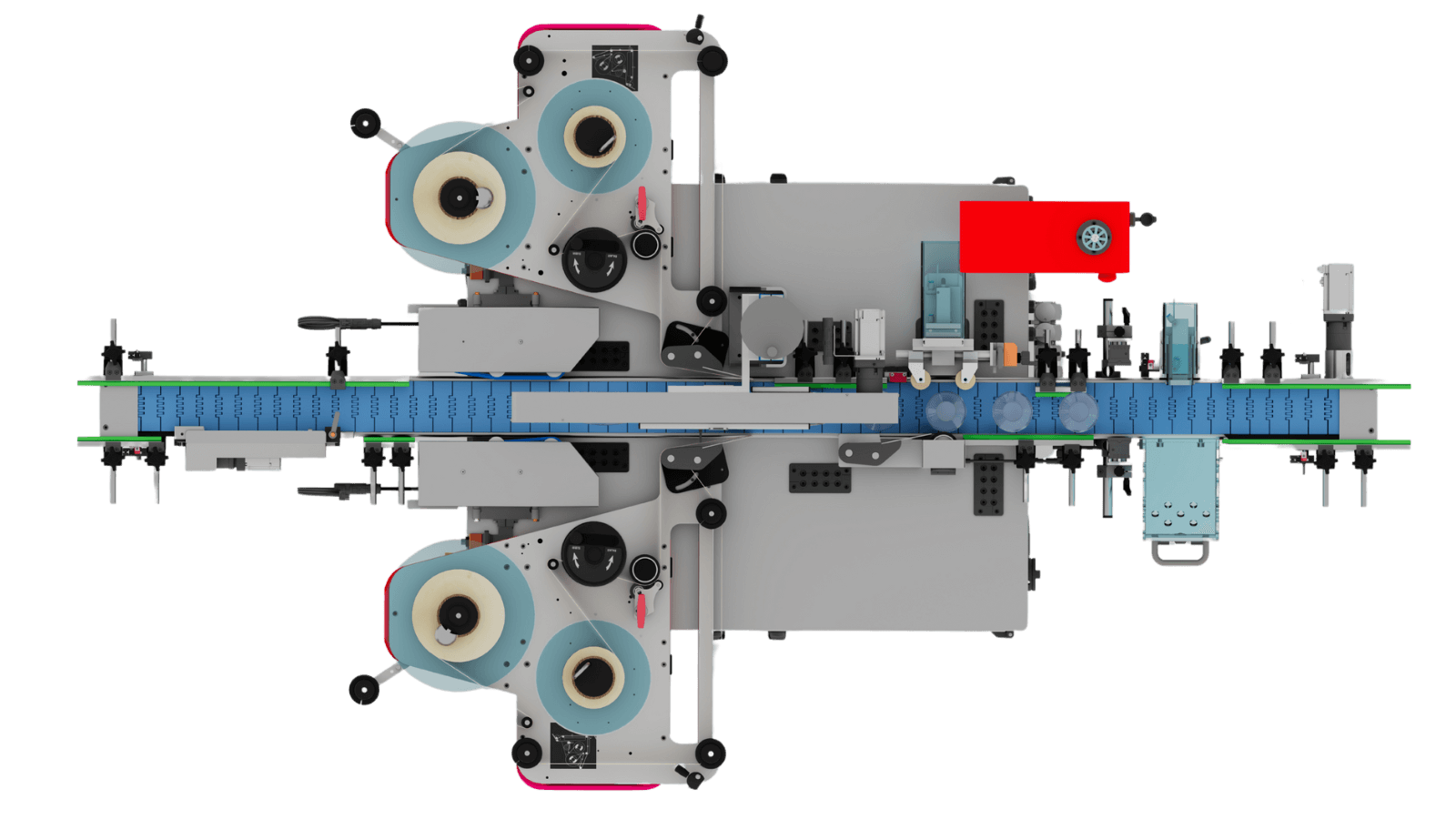

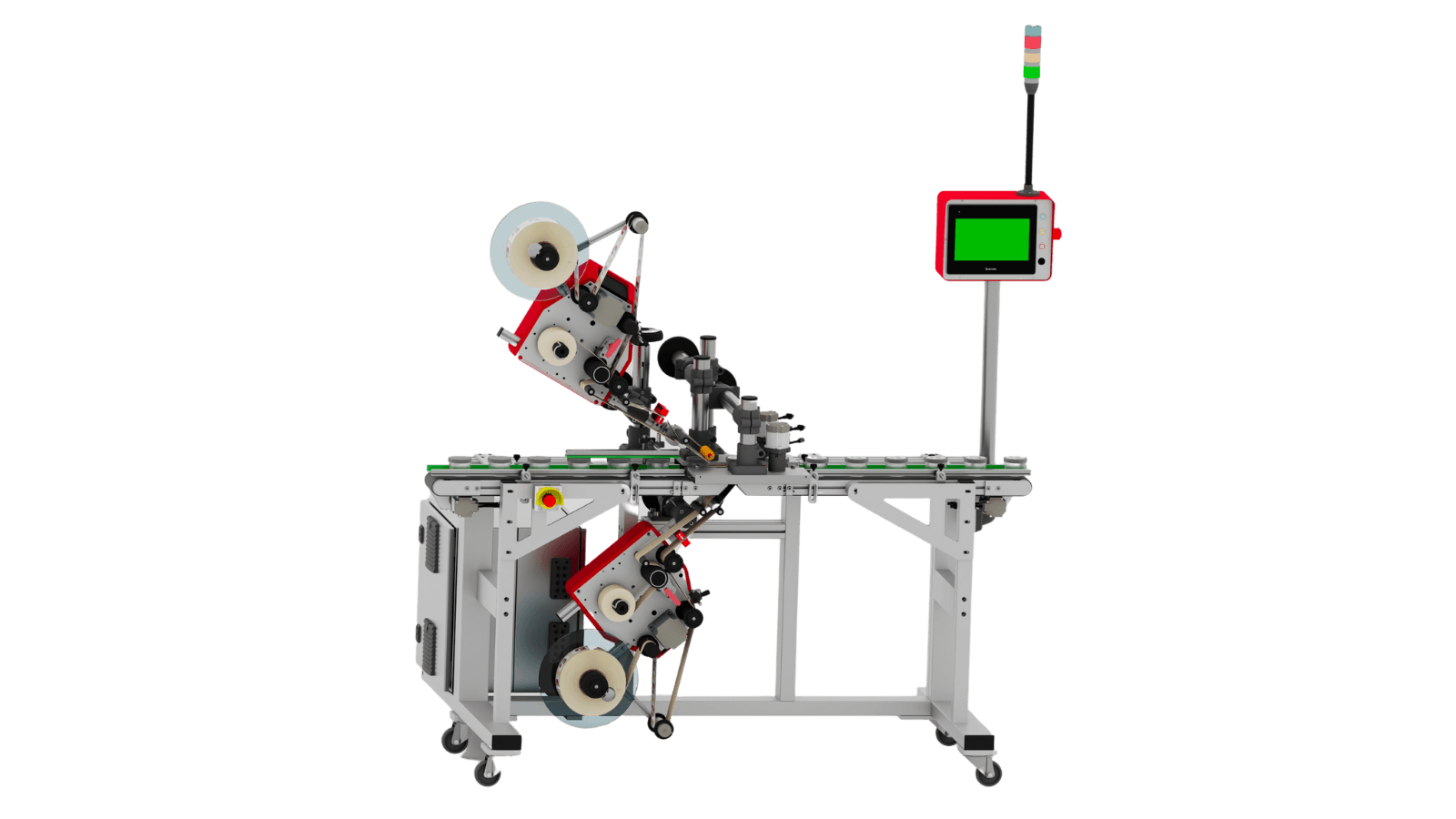

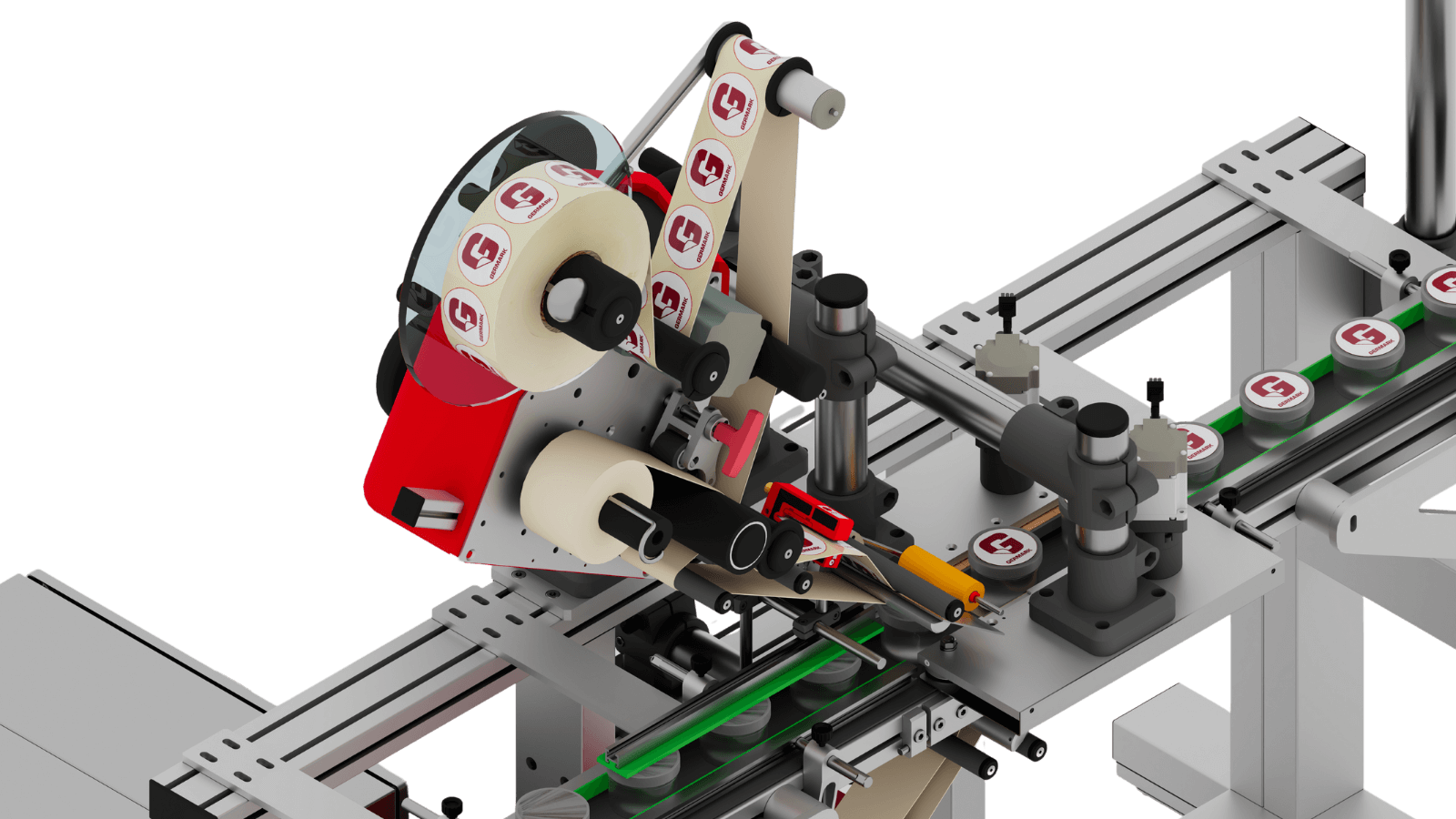

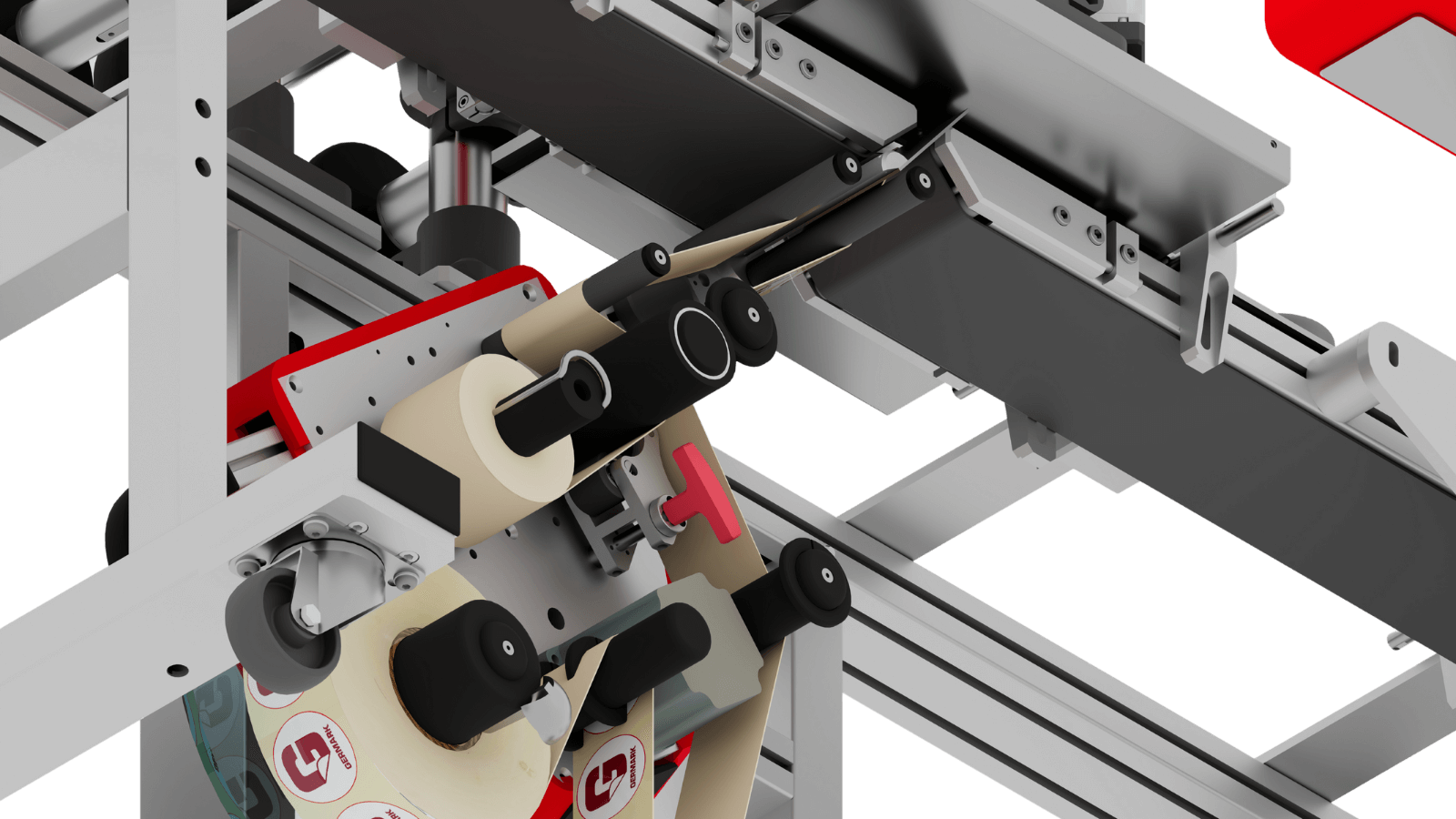

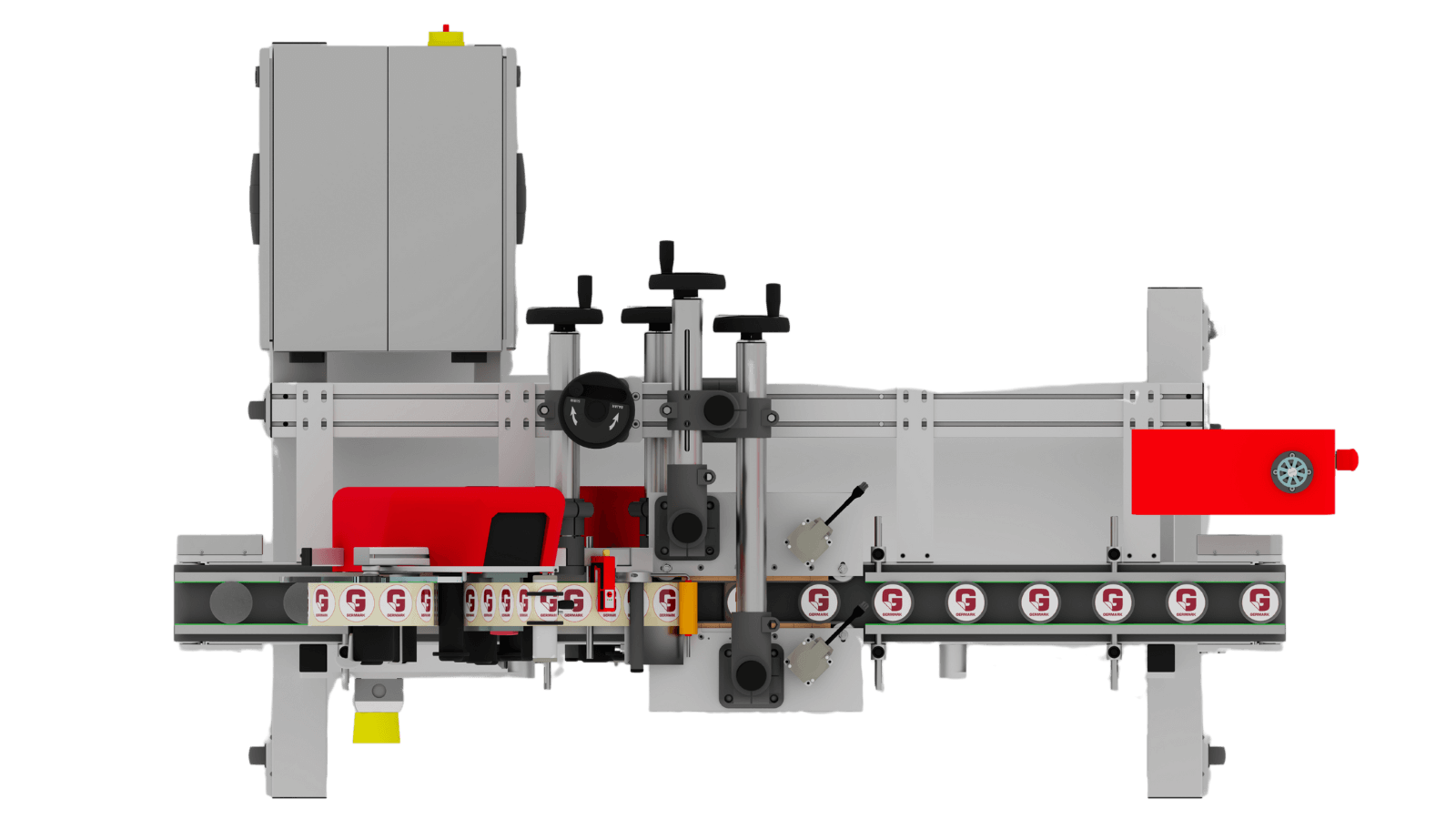

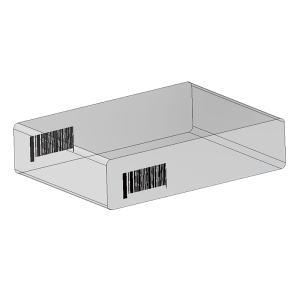

Top & Bottom

Linear labeling machines

- Cadence up to 200 ppm

- Beacon

- Top labeling

- Bottom labeling

- Printer

- End of reel control

- Paper break control

- Storage system for different formats

- Variable data detection camera (OCR)

- Label/product detection camera

- Non-conforming product rejection

- CFR21