Product labels

At Germark, we have the technical resources to bring all kinds of product labels to life, making them stand out at the point of sale. We work with exclusive materials such as wood, cork, velvet, leather, textiles, or metallic finishes, offering a variety of finishes. We have experience in numerous markets, including personal care, cosmetics and food.

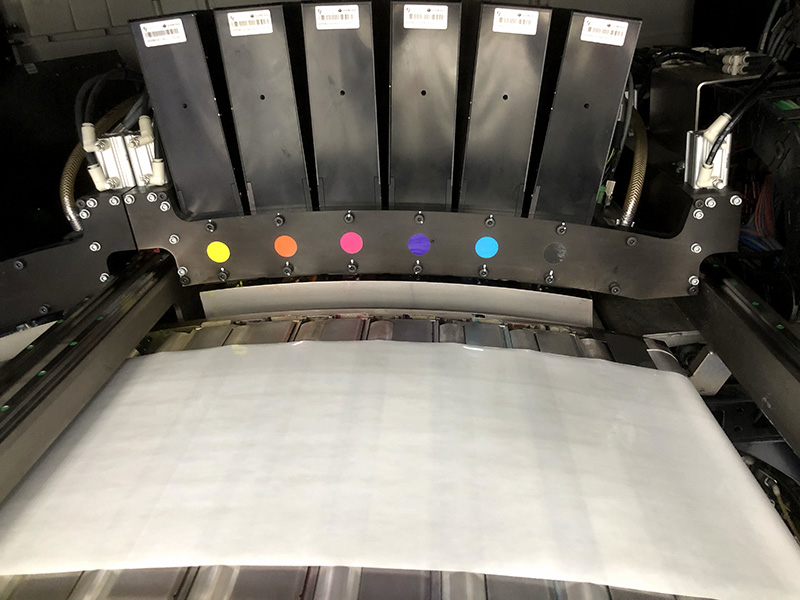

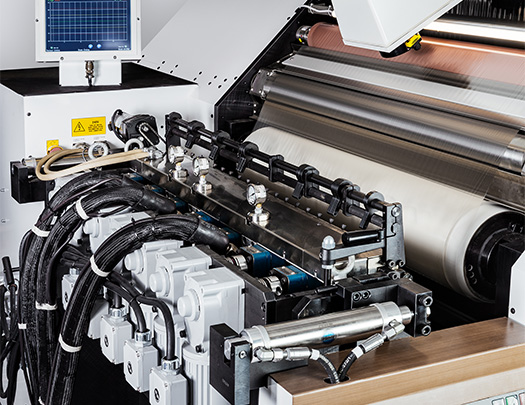

Printing techniques & finishes